At RePliForm we offer several finishing options. Internally we only offer copper and nickel plating. However, we have partnered with some amazing other companies that can help fulfill your need of precious metal plating.

Nickel

Buffed

This is one of our quickest post process finishes. Notice that the prep process for this part was standard (left picture) and the buffed finish was done to brighten the parts (right picture). Layer lines and defects can still be seen after the finish, but the difference of the finish is definitely noticeable.

Copper

Semibright

This is a standard finish, no post-processing done. Any layer lines and imperfections must be removed before plating as they will show through in the plating process. Semibright copper finishes are typically done for electrical purposes and sometimes used to as a jumping off point for more precious metals such as gold and silver.

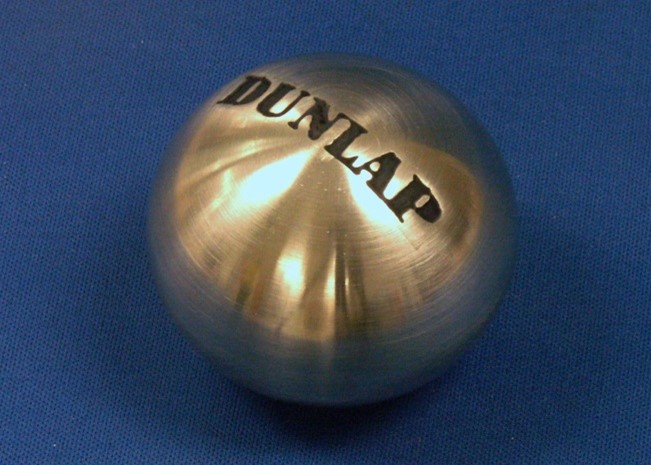

Polished

Any part requiring post processing must be hand sanded to 600 grit before sending for plating. All layer lines and imperfections must be removed otherwise they will show through the plating and may not come out during the finish steps. This is typically a midway step before sending the part to get gold, silver, chrome and other precious metals. If polished copper is requested, it is recommended to lacquer this shortly after plating.