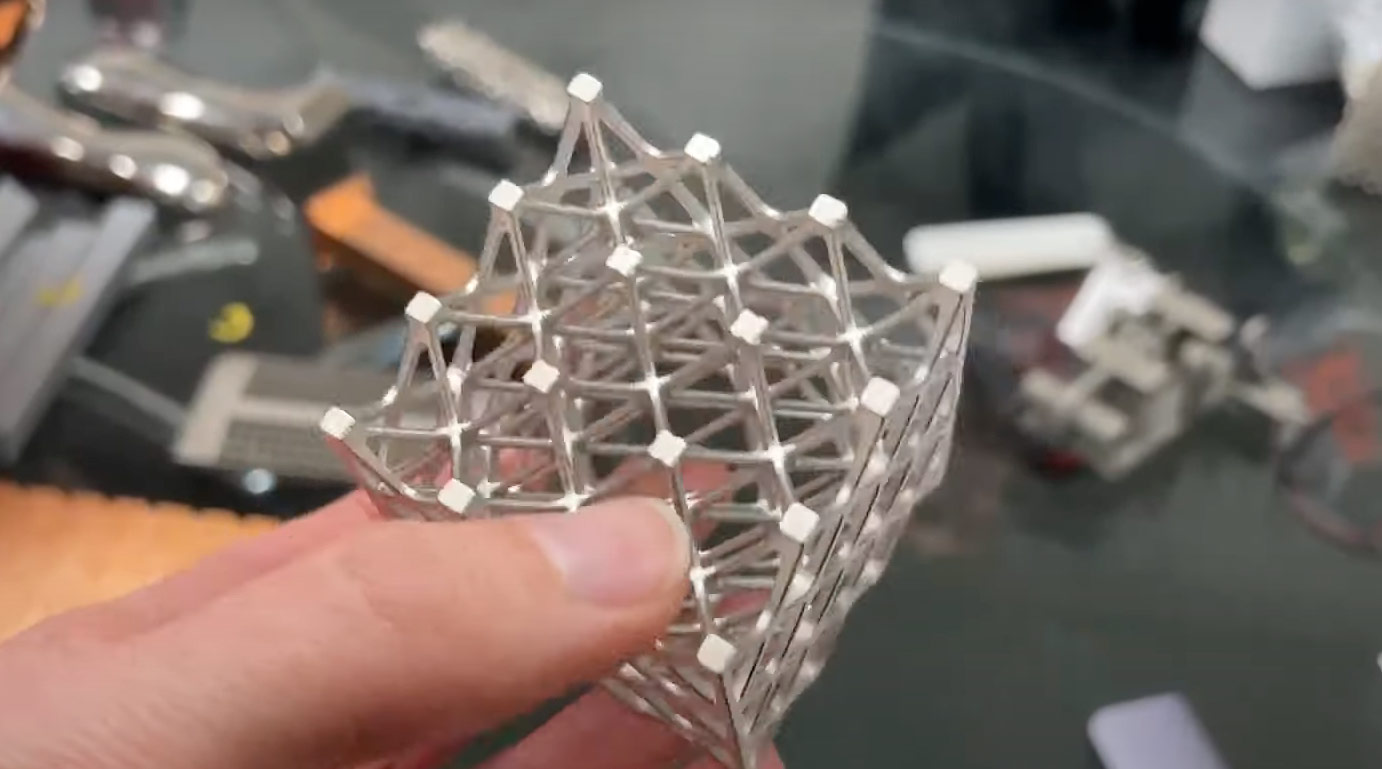

Electroplating is a process by which a thin layer of metal is bonded to another surface through electric current. It can also be used for applications in industrial design and product prototyping. It has many advantages over traditional manufacturing methods like 3D printing and CNC machining.

While 3D printing plastic has been around for decades, metal additive manufacturing is a new and fast-growing technology. For now, Metal AM has yet to see widespread adoption, but RePliForm Inc. aims to fill that gap between metal and plastic 3D printing methods.

Beyond Medical Devices & Equipment: RePliForm was incorporated in 2000, but our roots reach back much further to a time when electroplating and metal finishing was more than just a profession—it was an art. And we’re proud to say that we have fine-tuned our skills at metal finishing so well over these years that we can offer our clients a level of expertise not often found in today’s 3D printing industry.

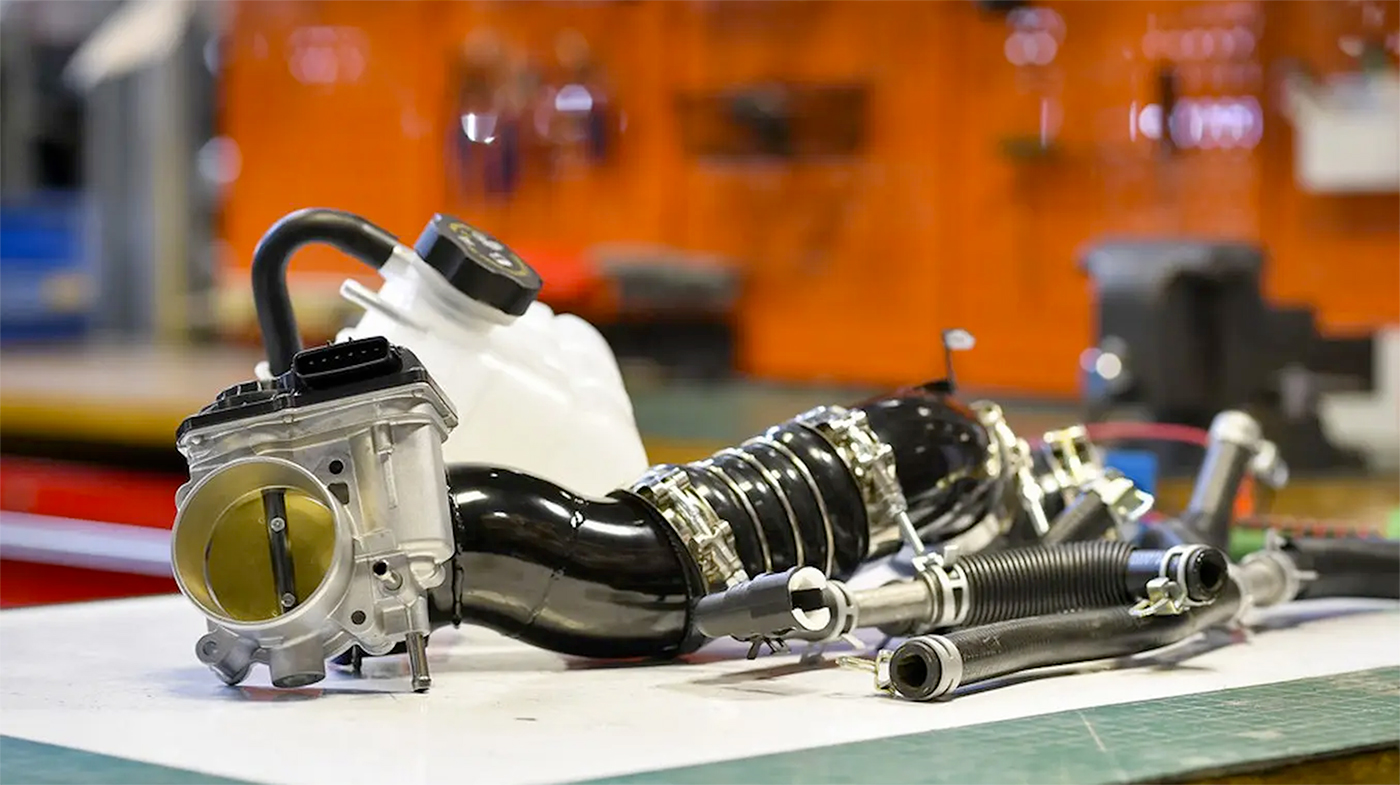

When it comes to plastics and metal 3D printing, no one is better qualified to fill that gap than RePliForm. Their platinum-based plating solution makes it possible for 3D printers to produce parts that are just as durable as those produced through more traditional manufacturing methods but at a fraction of their price point. This technology has shown tremendous potential in a variety of industries, from consumer goods and automotive to medical devices and aerospace.

Read the article: https://www.thefabricator.com/additivereport/article/additive/filling-the-gap-between-plastic-and-metal-3d-printing