3D Printing a New World of Possibilities

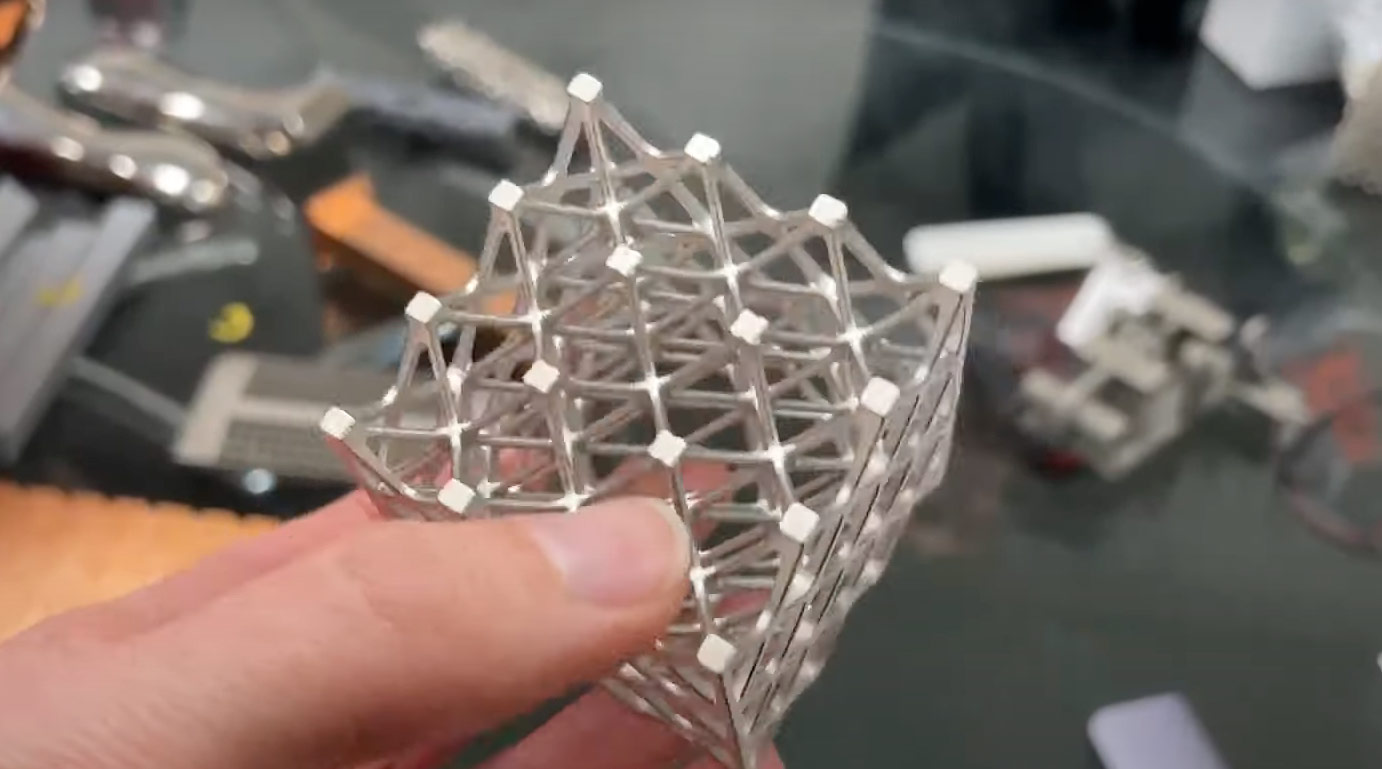

The 3D printing industry has seen an incredible amount of rapid growth in the past few years and it doesn’t seem to be slowing down anytime soon. One company in particular that stands out to me with their nickel & copper plating process called RePliForm Inc, has found a way to make 3D printed parts even stronger and more durable than they already are by using nickel & copper plating on plastics such as ABS, PLA, Nylon and more.

RePliForm, Inc., a leading provider of rapid prototyping services, is now offering its clients nickel plating and copper plating technology to give their prototypes significant strength and longevity.

If you’re looking to further increase your strength and longevity in 3D prints, nickel plating is a great option for achieving just that. RePliForm specializes in offering nickel and copper plating services for your designs, helping you save time and money while also giving you high-quality results that are sure to impress clients or potential buyers. We can even custom design our service based off of your needs, ensuring it’s done exactly as you envision it.

Electroplating nickel onto a printed part gives it a bright, shiny finish and prevents corrosion, which means you can expect those parts to be strong and last for a long time. Copper plating is often used when electronics are being printed so that they maintain high conductivity, but it’s also very popular with mechanical applications.

Nickel and copper plating is beneficial because it adds strength and longevity to 3D prints while maintaining a corrosion-resistant surface that does not interfere with plastic, ceramic, or glass printables. Nickel/copper coating is also quite durable as it can withstand exposure to water (liquid), acids, bases and oxidizing agents such as sodium hydroxide (lye). Lastly, nickel/copper plating has no adverse effects on human health upon contact.

Read the article: https://3dprint.com/61164/repliform-3d-model-plating/