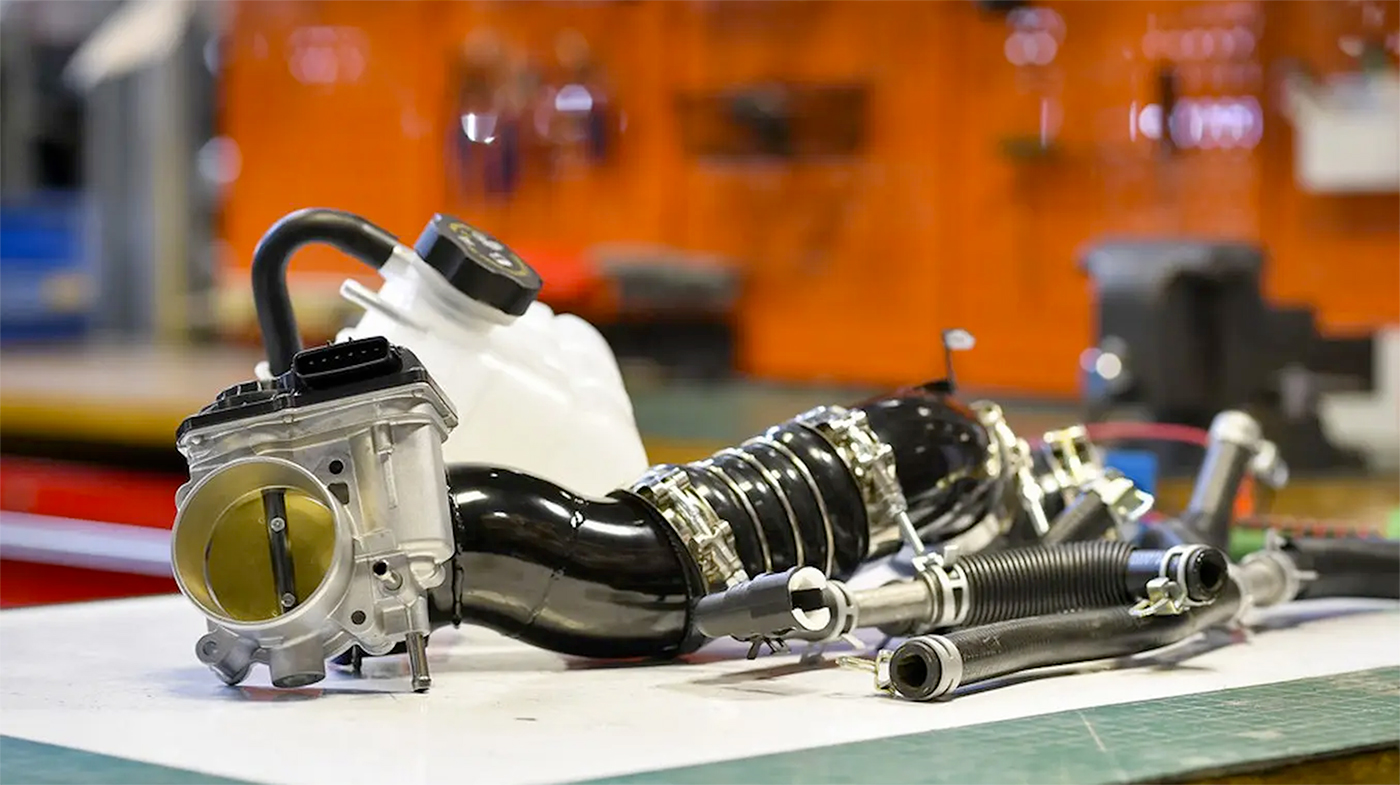

RePliForm is one of North America’s largest Nickel Plating lines and we specialize in nickel plating parts for a wide range of industries including Aerospace, Automotive, Medical & more. Our unique ability to coat complicated shapes in small quantities makes us a preferred partner among some of North America’s largest companies. We serve aerospace, automotive and medical industries across Canada and USA.

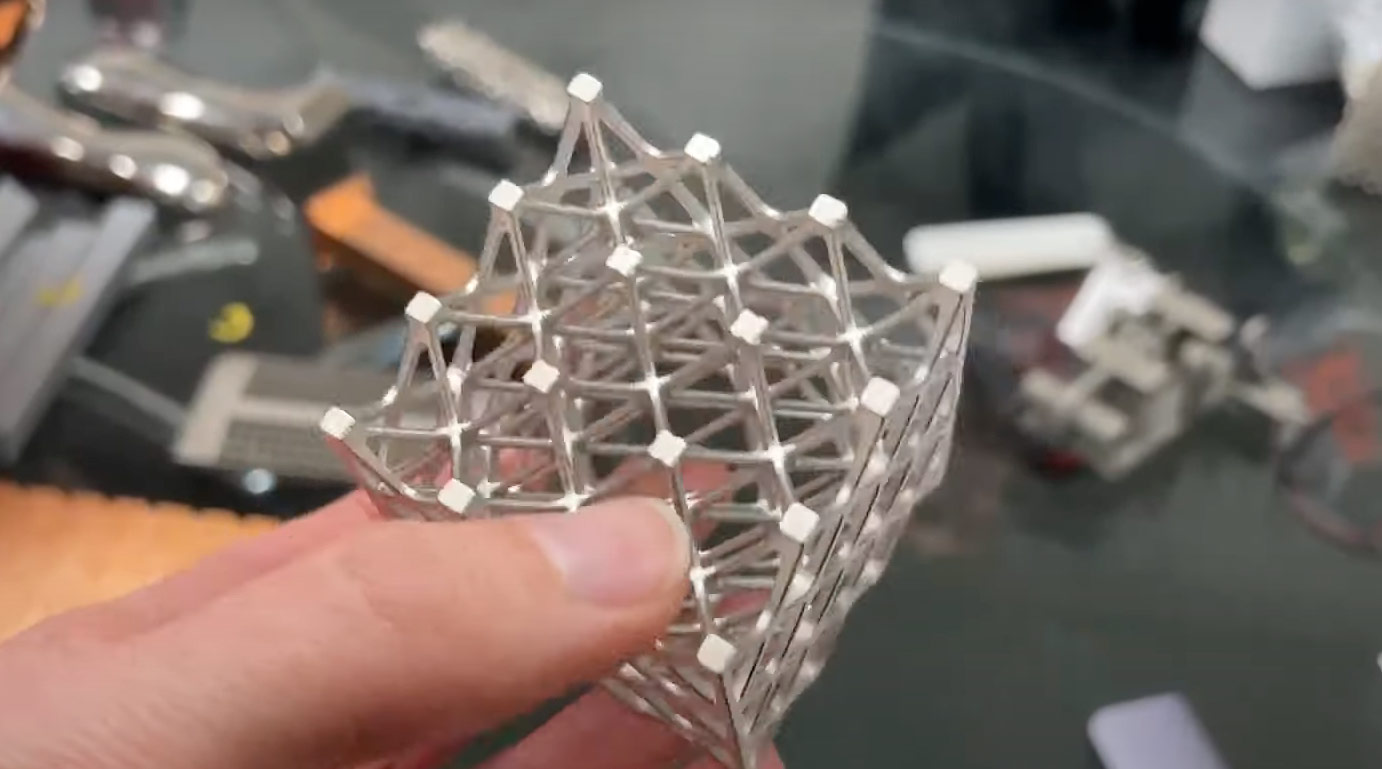

3D Printed Parts for any Industry: for years RePliForm has been busy plating a wide range of 3D printed parts including handles, housings and covers for medical equipment. The company has an edge here as they can also offer re-plating services to existing parts rather than having to start from scratch. If you’re looking to incorporate nickel plating into your 3D printing process, why not speak with RePliForm’s expert electroplaters?

RePliForm focuses primarily on providing engineers and designers with 3D printing electroplating solutions to help them accelerate their R&D process. By 3D printing parts for use in conductive, EMI shielded housings, aerospace manufacturers can save cost and time when prototyping electrical components. In addition to helping aerospace companies prototype their design concepts faster, RePliForm also provides end-users with high-wear surfaces—such as nickel coating—for those industrial applications that call for more durable parts.

Read the article: https://www.plasticsnews.com/article/20170919/NEWS/170919901/process-marries-plastics-3d-printing-and-electroplating